Advertiser Specifications

Uploading Ad Materials

Please upload all print ad materials through our online submission form or email to print-ads@magazinexperts.com.

Ads for Print Should be Provided as PDFs

Please supply a high-res PDF using the settings for PDF/X-1a:2001. Prior to creating the PDF, please ensure all elements of the ad are a minimum of 300 dpi in CYMK color format.

Printer Proofs

Advertisements supplied without a SWOP-certified color proof will be printed to SWOP (Specifications Web Offset Publications) standards. Visit swop.org for additional information on certified proofing and printing standards.

If an advertisement is submitted without an acceptable color proof, Construction Executive and its vendors assume no responsibility and/or liability for image, color, typographic and/or positioning irregularities.

Please send all printer proofs directly to the printer, and include the magazine name and scheduled month of insertion.

Teresa Davis

Royle Printing

745 S Bird St.

Sun Prairie, WI 53590

(608) 834-3668

tdavis@royle.com

For Questions About Your Print Ad, Please Contact:

Things to Know Before You Upload:

ABC Safety Standards Regarding Ad Materials

For Associated Builders and Contractors, which publishes Construction Executive, safety is a core value. ABC and its members believe that it is a moral obligation to protect anyone who sets foot on a jobsite.

In turn, Construction Executive requests that all persons or jobsites depicted in advertising images (i.e., stock art, commissioned photography, illustrations, etc.) demonstrate the use of personal protective equipment (PPE) and safety best practices that exceed OSHA standards.

The Top 10 things to look out for in images that depict jobsites and construction workers:

SAFE: Hard Hat, Safety Glasses, High Visibility Vest, Gloves

NOT SAFE: No Safety Glasses, No High Visibility Vest, No Gloves

1. The following personal protective equipment is required when on a jobsite: hardhat, industrial safety glasses with side shields, boots and high-visibility vest (plus gloves if doing actual construction work and earplugs if around loud noise, such as heavy equipment, power tools, etc.)

2. Personal fall arrest systems and equipment, including approved harnesses and lanyards that are properly worn and used, are required when someone is working at height (over 6 feet) or in a lift/hoist.

3. Guardrails are required on any vertical building under construction where the fall hazard is greater than 6 feet; a guardrail system should include a top rail, mid rail and toe board (ex.: 2”x4” lumber) or debris netting, to prevent unintended falling objects.

4. Vertical rebar that is knee height or below must have a plastic cap or be covered with a 2X4.

5. In general, jobsites should be tidy/organized, so keep an eye out for potential trip/fall hazards.

6. Equipment/roadway paths must be properly marked with tape or barricades to delineate between roadway and personnel areas.

7. No man-made hoists or structures are allowed

8. Anyone on a ladder must have three points of contact (e.g., two feet and one hand).

9. Welders must wear a full helmet and anyone cutting/grinding must be wearing a face shield that meets ANSI Z87.1; safety glasses must also be worn under all helmets and/or face shields if visible.

10. Equipment/vehicle operators must be wearing a seatbelt while driving and no mobile device (cell phone, tablet) should be visible/within hand’s reach.

ABC must review all ads for safety and reserves the right to reject advertising materials that do not meet the association’s safety mission. Upon rejection of materials for safety violations, advertisers will be given at least five business days to submit new materials for review.

How to Prepare Your Ad for Print: Ad Do’s and Dont’s

DO

DO NOT

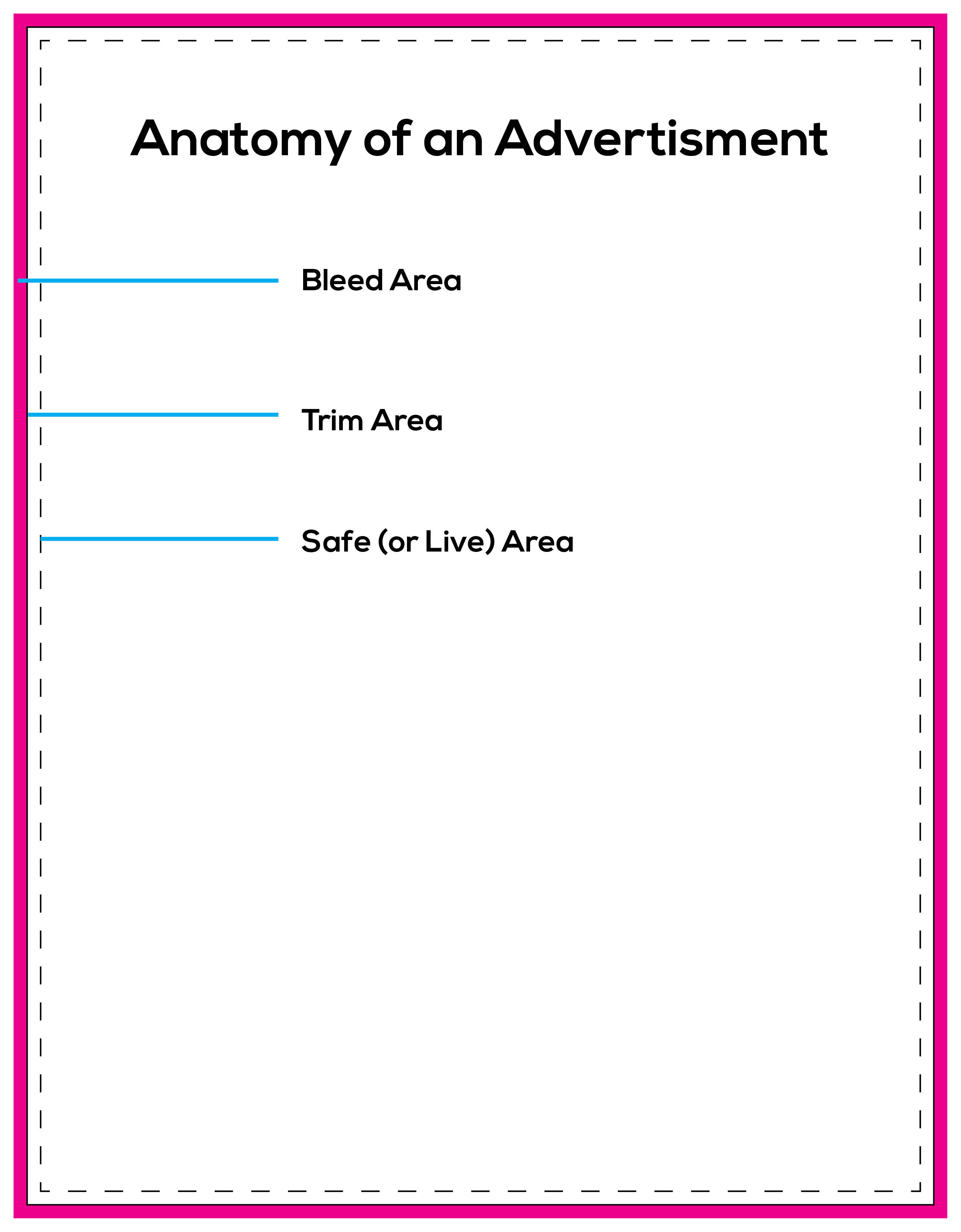

Anatomy of an Advertisement

Common Terms

Bleed: Extend your background to fill the full ‘bleed area’ – It will make sure you dont end up with white edges when the pages are trimed.

Safe (or Live) Area: Keep ALL important design elements, like text, logo, icons, etc. inside this area. (Not your background – that still needs to run to the edges of the bleed.)

Trim: Where we aim to cut the ad. Slight shifting may occur when trimming, so we leave a little wiggle room.

Gutter: Please leave a .5” “gutter” in the center of your two page spread. This is so you will not lose any important information when the magazine is bound and folded.

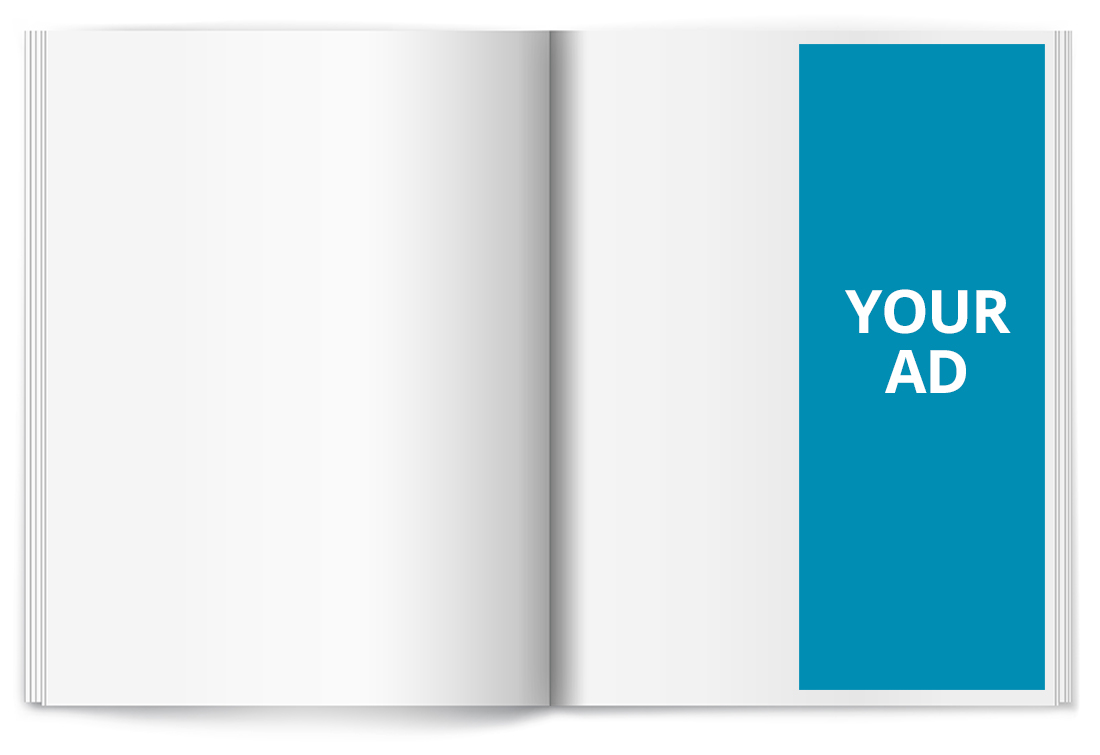

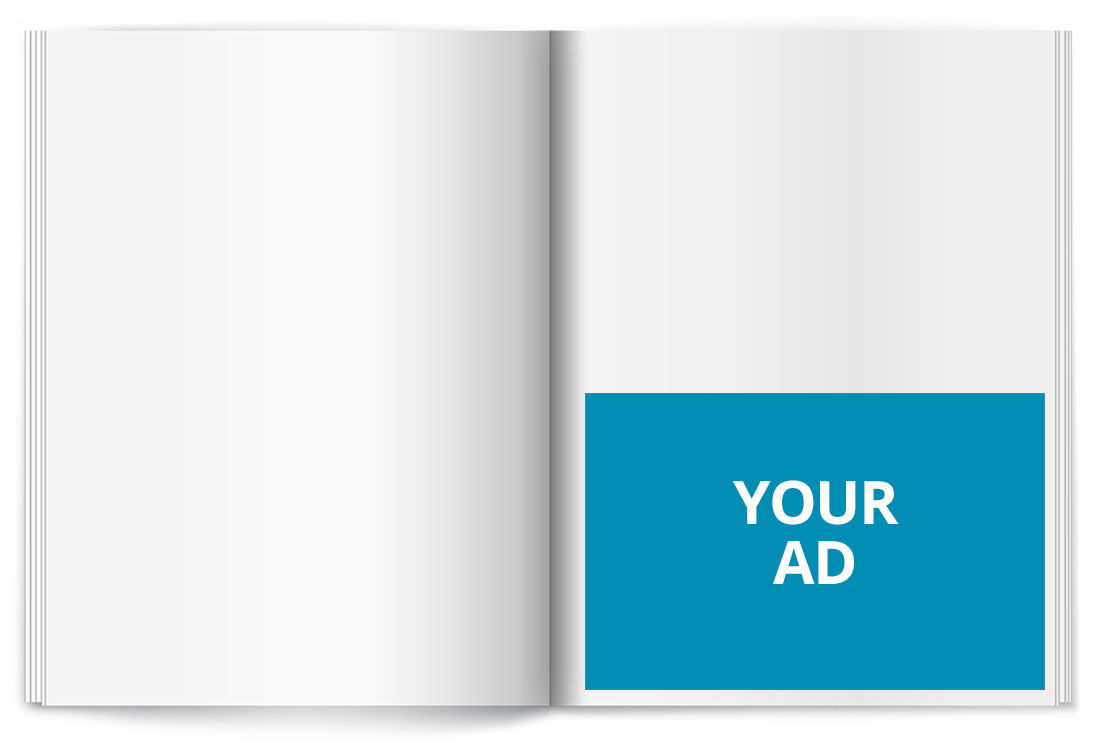

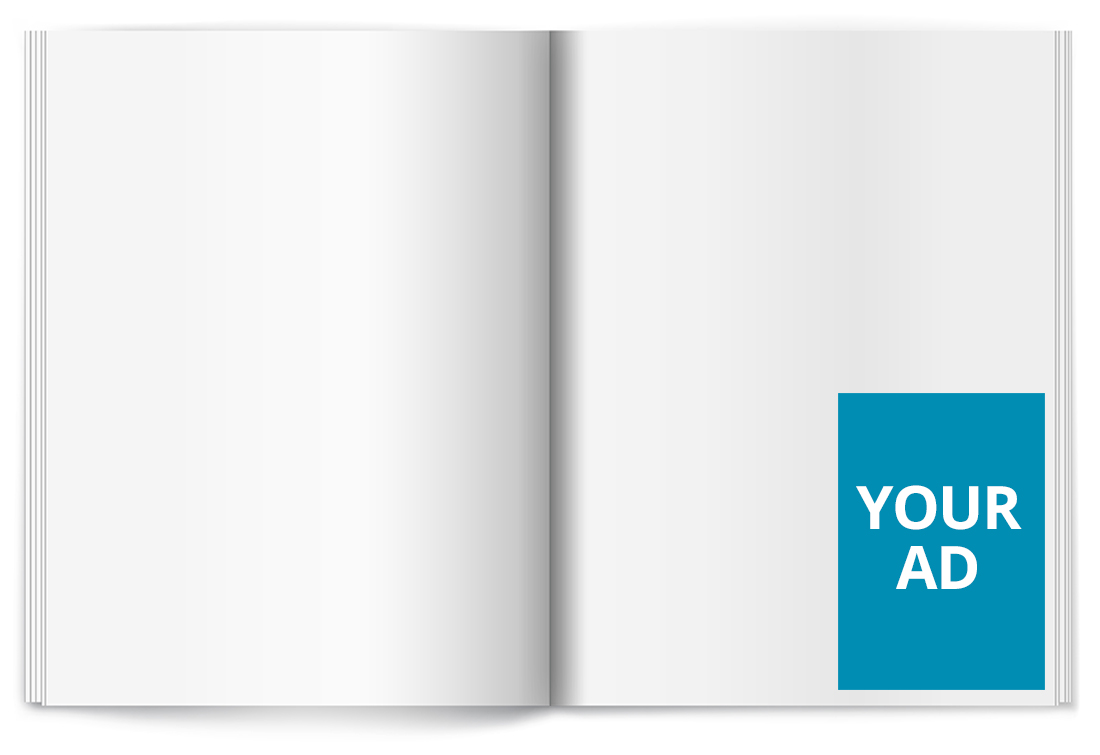

Print Ad Sizes

Note: All measurements are listed with the width of the ad first, followed by the height.

Ready to Upload?

Please upload all print ad materials through our online submission form or email to print-ads@magazinexperts.com.

Superlative Claims

Claims made in advertisements placed in Construction Executive must be truthful, non-misleading, or – when appropriate – backed by scientific evidence. If a claim must be qualified in order to render it non-misleading, that qualification must be clear and easy to read. Construction Executive requires proof that a claim be true prior to publishing it. Claims of “#1,” “Best,” “Only,” or other superlatives that compare company or product attributes must cite a third-party source of method for their claim.

Disallowed Examples:

XYZ is the #1 provider in the field.

XYZ is the best software for contractors.

XYZ is the only company that offers this service.

XYZ is the leading company in a certain industry.

Allowed Examples:

XYZ is rated the best-value software for contractors by QRX Group (include hyperlink to source if digital)

XYZ is rated the best value software for contractors* *by QRX Group, 2016

XYZ is a leading company in a certain industry